2025-10-02

Longer service life for heavy-duty hoists

RINGSPANN presents technology solutions for optimising crane drives

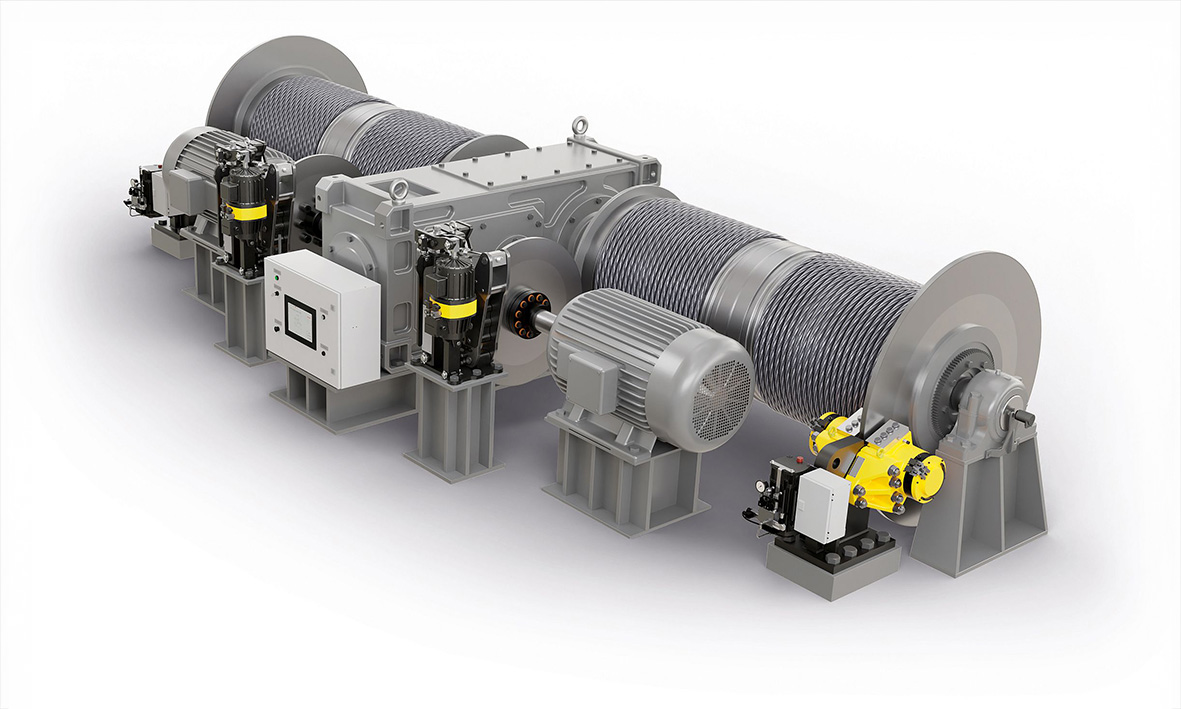

A few months ago, RINGSPANN introduced its new electro-hydraulic DX disc brakes, which are now used by a number of crane builders when designing holding and emergency stop systems for the hoists of harbour and container cranes. As a further result of its brake development, the company is now presenting three technological solutions that can significantly improve the performance and service life of heavy-duty hoists. Read here about the drive problems that can be eliminated.

Bad Homburg, October 2025. – „The electro-hydraulic DX series disc brakes from RINGSPANN are designed for a high shifting frequency on high-speed discs and feature new, energy-efficient thrusters. They offer operators numerous advantages both in the design of heavy-duty hoists and during their operation and service. The first harbour crane builders therefore decided to use these brakes immediately after the market launch at the end of 2024. However, in order to offer hoist manufacturers access to its technological know-how in the field of industrial brakes in addition to providing innovative disc brakes, RINGSPANN has developed several system solutions that improve the performance of the hoists and increase their service life. They start at four neuralgic points in hoist and gearbox technology.

Avoiding harmful flank changes in the gearbox

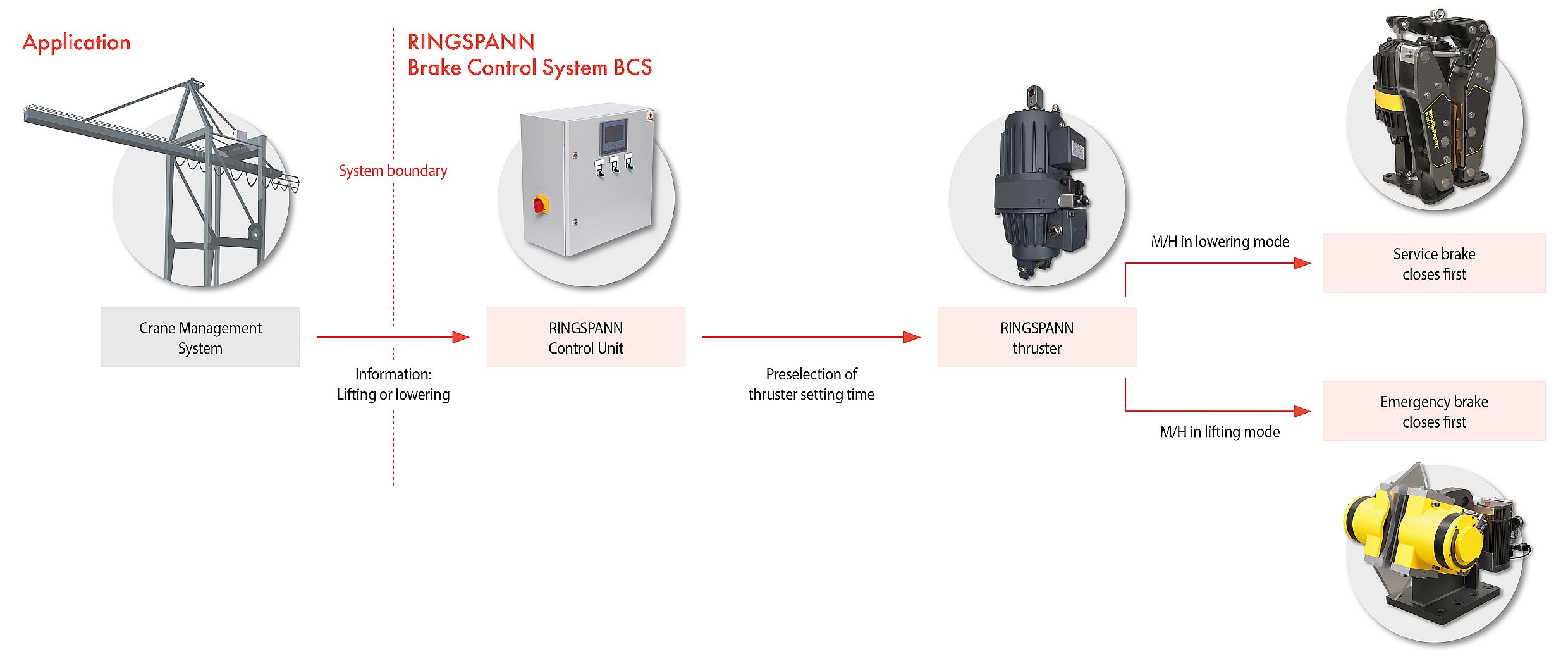

The flank change of the transmission gears of the main hoist is a negative effect that occurs during emergency stops. First of all, it should be noted that the driving lifting force is the motor, but when lowering, the load acts as the driving force (the motor then only controls the movement and prevents free fall). To eliminate the change of flanks, it must now be ensured that the emergency stop brakes of the rope drum close first when lifting, while the electro-hydraulic service brakes on the output shaft of the motor have priority when lowering. "To achieve this, we have developed a stand-alone solution where the crane's control system only needs to provide the information on whether the crane is operating in lifting or lowering mode. Everything else is taken care of by an electrohydraulic thruster that closes with two preset closing times, and a control unit that selects the respective closing time in advance. The system is easy to integrate – both in new cranes and in retrofits," says Martin Ohler, Brake Business Developer at RINGSPANN.

Adaptive and gentle braking

The second system solution from RINGSPANN addresses the problem of the harmful effects of torque peaks. It should be noted that when selecting hoist brakes it is usually assumed that maximum lifting speed and maximum lifting load are simultaneous. Under these conditions, the braking force of all brakes offers sufficient counterforce in the event of an emergency stop, but these extremes are not a normal scenario. If, for example, the crane only has to convey half of the maximum payload at a reduced speed, the braking force proves to be too great. "As a result, high peak torques occur in the gearbox, the steel structure has to withstand strong shocks and all load-bearing bearings are under high loads," reports Martin Ohler.

To prevent all this, RINGSPANN has developed an adaptive braking system consisting of three components: a control unit that selects valve configurations for different incidence times; a hydraulic power unit that can be used to control the incidence time of each emergency stop brake individually; and several brakes on the rope drum, which allow different braking force variants. The control system receives information from the crane management system on the mode in which the crane is working. It distinguishes between several load cases – such as fast coasting – and triggers a predefined valve configuration on the hydraulic power unit. "A specific brake configuration is then activated for coasting, which provides a sufficient – but not oversized – braking force with which the hoist is stopped safely. All other brakes are automatically activated with a short delay, and the crane is secured at a standstill at full braking power. The system can be expanded with any number of brakes and load cases," explains Martin Ohler.

Adaptive braking of the boom hoist

The third technology solution from RINGSPANN is also an adaptive braking system and focuses on a routine case: the container crane is out of operation, its water-side boom is raised and is set vertically for reasons of traffic safety and weather protection. If an emergency stop occurs when the boom is raised or lowered, all brakes are applied with maximum force. If the boom is close to the vertical resting position at this moment, harmful torque peaks occur in the gearbox, bearing and steel construction. The load torque also increases when the boom is lowered – increasing the closer it gets to its horizontal working position. The maximum braking force is usually selected so that the boom can be stopped and held even near the working position.

In both cases, the adaptive braking system from RINGSPANN protects the transmission, bearing and steel structure from stress and prevents their premature wear. It consists of four components and allows the braking force to be specifically adjusted: an absolute rotary encoder attached to the bearing of the rope drum provides information about the current boom position via crane management. A control unit picks up the signal from the encoder and switches different valve states in the hydraulic power unit of the emergency stop brakes based on it. By combining special locking valves, the hydraulic power unit enables both immediate braking and braking with initially reduced, then increasing starting braking force. In conjunction with the hydraulic power unit and control unit, one or more emergency stopping brakes finally initiate a braking process with different braking forces. What all three RINGSPANN technology solutions have in common is that they can be adapted to the customer’s needs and always dock directly onto the crane’s management system. ms

Ventilation devices and sensor technology individually selectable

The new DX brakes from RINGSPANN can be equipped with various thrusters from the company’s production. They are suitable for braking torques from 1,700 to 28,100 Nm and clamping forces from 9.5 to 80 kN. Their function is to release the brake via an electrohydraulically generated counterforce to the brake spring. To do this, an electric motor, an impeller or gear pump and a piston cylinder interact inside them. In addition, RINGSPANN offers a large selection of sensors for DX brakes. Inductive sensors are standard for monitoring brake release, brake locking, pad wear and manual unlocking. Sensors of other types are optionally available, measuring probes with ATEX certificate and SIL approval, load measuring pins for measuring contact force, analogue sensors for checking reserve stroke as well as wear and temperature of the brake pad.

electrohydraulic thruster that closes with two preset closing times and a control unit that selects the respective closing time in advance. Image: RINGSPANN

in a brochure. Designers, operators and maintenance engineers can also find information about DX brakes and adaptive braking. Image: RINGSPANN